Elevator energy-saving solution provider: The hot summer is often the season when elevator failures occur frequently. Elevators tend to malfunction more frequently in high-temperature weather, and high temperatures in elevator machine rooms can easily lead to elevator equipment crashes. According to relevant safety technical specifications, the air temperature in the elevator machine room or machinery equipment room should be maintained between 5-40 ℃. If it exceeds this range, the failure rate of the elevator will increase by about twice. There are three main reasons for the high temperature in the computer room: 1. The outdoor temperature is too high, for example, direct sunlight increases the indoor temperature; The braking resistor on the control cabinet of the elevator machine room is the largest heat source; 3. The motor host is heating up.

If there are no good ventilation and cooling measures in the computer room during summer, once the temperature exceeds 40 ℃, it will cause electronic board crashes, contactor contacts to burn out, and other situations (an elevator has more than ten contactors, and one contact burning out can cause elevator malfunctions); And the elevator machine room operates at high temperatures for a long time, which can easily lead to circuit failures, such as sudden inability to open the elevator doors, people being trapped inside the elevator, malfunctioning elevator buttons, sudden power outages, etc.

IPC Plus can solve the hidden danger of high temperature in elevator machine rooms in summer for you

According to Anhui Business Daily, the Anhui Provincial Quality Supervision Bureau reported the results of the 2016 provincial elevator installation quality supervision spot check: six inspection teams of the Anhui Provincial Quality Supervision Bureau inspected a total of 149 elevators in 16 cities and two directly administered counties in the province, involving 122 elevator installation units. Safety inspectors conducted comprehensive inspections of 28 major items and 46 minor items, including elevator machine room temperature, main switch, emergency lighting and alarm device, grounding protection, speed limiter, etc. The average compliance rate of installation quality for a single elevator is 87.69%, with the highest being 100% and the lowest being 68%; The average conformity rate of elevator installation quality is 88.6%, with the highest being 100% and the lowest being 42.28% (elevator machine room temperature). No key non conformities affecting the safe operation of the elevator were found.

The person in charge of the Special Office of the Provincial Quality Supervision Bureau introduced that from the content of elevator installation inspections, the installation projects with a compliance rate of less than 85% mainly include machine room temperature, emergency lighting and alarm devices, grounding, end fixing, mechanical component protection, counterweight fixing, guide rails, and buffers. The three items with the lowest compliance rate are computer room temperature, buffer, and guide rail. Upon investigation, the quality supervision department found that due to the lack of facilities to maintain a temperature of around 40 ℃ in the elevator machine room, the temperature in the room was either too high or too low. Some users, in order to save money, believe that high temperatures will not cause frequent elevator malfunctions and serious consequences such as people being trapped; Most elevators do not have public mobile communication network signal coverage, which poses a hidden danger to elevator emergency rescue.

How to prevent the hidden danger of high temperature in elevator machine rooms has always been one of the main issues for the safe operation of elevators. The most common solutions are as follows:

1. In the case of air circulation, modern elevators have built-in cooling fans; Old style elevators can use fans to some extent to cool down.

2. For safety reasons, most elevator machine rooms are enclosed, and air conditioning must be installed to cool them down when air circulation cannot be achieved.

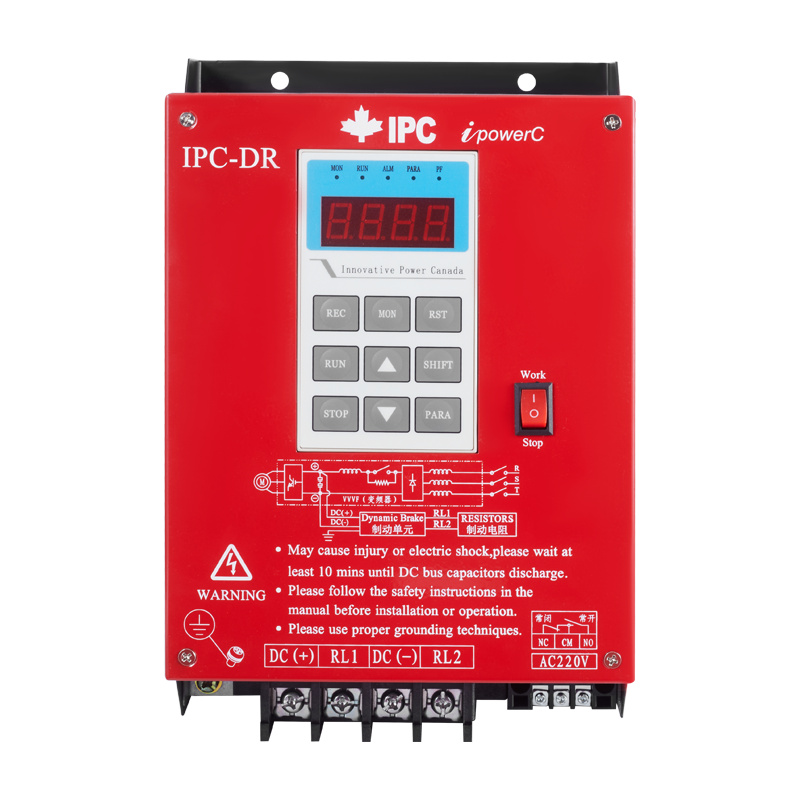

But these two methods can only have a temporary effect and not a fundamental one. In hot weather seasons, the cooling effect of fans is limited. Once the air is not circulating, the heat generated by resistors cannot be dissipated, and the cooling effect is very small; The air conditioning in the computer room must run continuously for 24 hours, and over time, the air conditioning may malfunction, which poses a significant safety hazard to the elevator. In this case, the use of energy-saving feedback devices in elevators can effectively solve the problem of high temperature in elevator machine rooms. It can convert excess energy (including kinetic and potential energy) that used to be consumed by resistance heating into regenerative electrical energy through electric motors and frequency converters. This method not only reduces the maximum heat source in the elevator machine room, but also filters and processes the generated regenerative electrical energy, and feeds back the standard electrical energy to the grid for use by other electrical equipment. Greatly reducing the temperature of the computer room while minimizing the failure rate of equipment in the room, and also playing a role in energy conservation and environmental protection.

Install the PFE elevator energy-saving device produced by Shenzhen IPC Technology Co., Ltd., using multiple cutting-edge technologies and compatible with all brands of elevators. After multiple on-site practical tests, the comprehensive energy-saving rate has reached 20%~50%. The efficiency of regenerative energy recovery is as high as 97.5%. Easy installation, debugging, and operation, convenient maintenance and upkeep, can reduce or even eliminate the use of air conditioning, fans, and other heat dissipation devices. At the same time, by no longer using resistors for heating, it invisibly increases the service life of other components and reduces a lot of repair and maintenance time.

English

English Français

Français 日本語

日本語 Русский

Русский Deutsch

Deutsch Español

Español Português

Português العربية

العربية भारत गणराज्य

भारत गणराज्य Việt Nam

Việt Nam Nederlands

Nederlands slovenščina

slovenščina Türkçe

Türkçe Polski

Polski Română

Română Magyar

Magyar 한국어

한국어 ไทย

ไทย Čeština

Čeština Български

Български Україна

Україна اردو

اردو فارسی

فارسی Bahasa Indonesia

Bahasa Indonesia Bangladesh

Bangladesh Italiano

Italiano Norsk

Norsk Dansk

Dansk Suomi

Suomi беларуская мова

беларуская мова Eesti keel

Eesti keel Latviešu valoda

Latviešu valoda svenska

svenska slovenčina

slovenčina isiZulu

isiZulu Icelandic

Icelandic አማርኛ

አማርኛ Kiswahili

Kiswahili هَوُسَ

هَوُسَ עברית

עברית